The Importance of Modified Atmosphere Packaging

In recent years, consumers are seeking minimally processed products with extended shelf life which have increased progress in packaging technologies to fulfil this demand. An example of a packaging technique to extend shelf life is Modified Atmosphere Packaging (MAP). MAP can extend the shelf-life and maintain the visual appearance of fresh meat with a combination of carbon dioxide, nitrogen and oxygen (Stanbridge and Davies, 1998).

To find out more about MAP, check out our previous blog here.

The Challenges of the implementation of MAP

Successful implementation of MAP requires a holistic approach that includes the understanding of pre-slaughter, post-slaughter physiology, cold chain logistics and the interaction of these factors with packaging design. Due to the high requirements of implementing MAP, producers must control the packaging process and implement multi-level quality assurance to reach the highest level of process safety and thus, product quality.

A challenge of MAP is the protective atmosphere must be optimised for a specific product before the pack is sealed which is a two-stage process. Firstly, a vacuum is first used to remove as much oxygen from the system as possible. This is followed by, a flush of carbon dioxide, nitrogen and oxygen to meet the desired gas concentration.

Nitrogen in MAP acts as a sterile filler to dilute the concentration of oxygen and carbon dioxide in the package, thereby reducing the onset of oxidation while also helping to ensure package stability. Carbon dioxide has bacteriostatic and fungistatic properties and its effects are due to its ability to penetrate the cellular membrane which causes intracellular pH changes and disrupts the internal enzymatic equilibrium. The gas selectively inhibits the growth of gram-negative bacteria, such as pseudomonads and other related psychrotrophs, which otherwise grow rapidly and produce off-odours and off-flavour. Here is the link to the article, to find out more.

As agricultural products have different metabolisms from each other, the MAP system must balance the processes of respiration, transpiration, and gas permeation through the packaging that will be occurring simultaneously. For example, potatoes and tomatoes have generally low respiration levels in comparison to asparagus, broccoli and mushrooms which have a high rate of respiration. Once fruit and vegetables are harvested, cut and handled, product deterioration accelerates as the respiration rate is increased, the tissue becomes more susceptible to oxidative discolouration, and microbial growth is enhanced. Therefore, it is critical to match the oxygen transmission rate (OTR) of the packaging material with the respiration rate of the product. The successful implementation of MAP, depending on the product type, can double the shelf-life.

Discolouration of meat

In fresh beef, premature discolouration refers to beef turning brown before the expected best-before date. As consumers associate the bright red colour of meat with freshness and high-quality products, reducing the amount of discolouration is vital to reduce food waste and maximising producers’ and retailers’ revenue. Various intrinsic and extrinsic factors contribute to premature browning such as the age of the meat, post-mortem muscle pH, packaging and supply chain conditions.

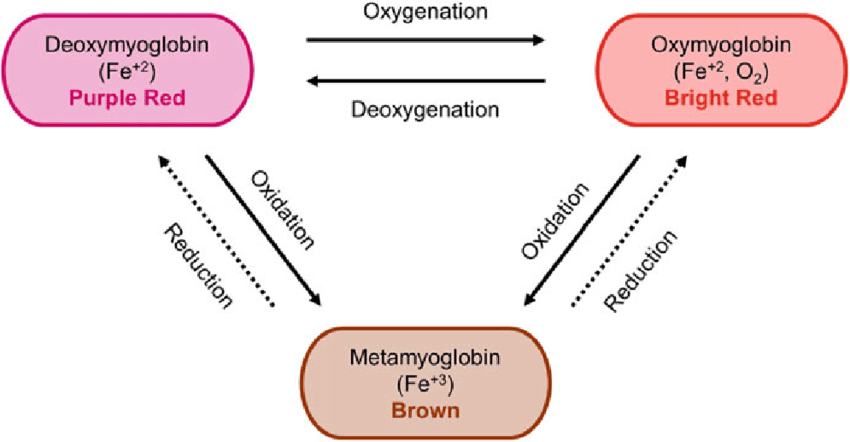

The optimum colour of fresh red meat is a cherry red pigment (Oxymyoglobin) which is highly unstable and short-lived. The colour of meat can be controlled by changing the composition of the atmosphere in the packaging and applying adequate high-barrier films (Šuput et al., 2012), thus improving the attractiveness of the product. Fresh meat which is protected from contact with air (vacuum packaging) has a purple-red colour which comes from myoglobin. When exposed to air, myoglobin forms the pigment, oxymyoglobin, which gives the meat an appealing cherry-red colour. The exposure to retail lighting as well as the continued contact of myoglobin and oxymyoglobin with oxygen leads to the formation of metmyoglobin, a pigment that turns meat brownish-red.

Many factors affect oxymyoglobin oxidation: temperature, pH, partial O2 pressure and lipid oxidation (Faustman and Cassens, 1990). Oxymyoglobin oxidation is favoured by higher temperatures (Brown and Mebine, 1969), lower pH values (Lindahl et al., 2001) and the presence of non-heme iron.

Failures of MAP resulting in Pre-mature discolouration

The consumer uses colour as a measure of meat freshness and quality, for example when bright red beef and discoloured beef are sold together, shopper discrimination against the discoloured meat increases with increases in metmyoglobin content. As colour is vital in a retail setting, it is desirable to know which factors are most significant in determining colour stability and pre-mature discolouration in meat.

- Incorrect use of gas

One of the most important aspects of MAP is the combination of carbon dioxide, oxygen and nitrogen within the atmosphere. The correct MAP gas mixture ensures the products are of high quality by retaining their appearance, taste and texture.

The MAP gas atmosphere must be chosen with some consideration for the product composition, for example with fresh meat, different animals and cuts of meat will have different metabolism so the mix must balance the product’s respiration and transpiration. For example, in low-fat products such as chicken, a high carbon dioxide concentration is required to inhibit the growth of microorganisms.

Currently, the random inspection of finished packaging is a destructive test. This will indicate the concentration of the gas mix to ensure the level is correct. However, a better alternative to manual offline detection is the 100% in-line technology from Senoptica. Find out more about Senoptica’s technology here.

2. Issues with machinery, tools or materials

Issues surrounding the incorrect pressure, incorrect temperature and damaged parts of the packaging tools can result in MAP failure. Therefore, high-quality equipment with regular inspection of the equipment and product inspection will ensure the equipment is set to the correct parameters.

3. Mechanical leaker

A properly sealed package will ensure the maximum shelf life of a product is reached and is especially important in perishable items such as salad, baked goods, dairy, and pet food. If there is a leak in the packaging, oxygen will be able to permeate the product and begin or accelerate the decomposition process.

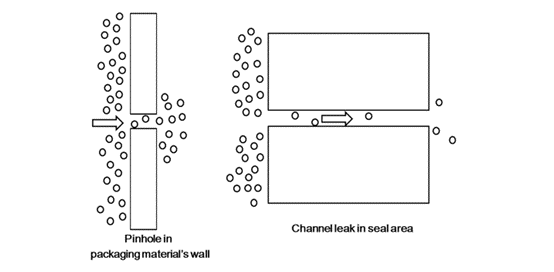

Typically, the sealing areas in flexible packaging are bonded together by the application of heat. Therefore, these areas are where most leaks would be expected to occur. Generally, two types of leakers can be classified as pinholes and channel leaks. Pinholes are breaks in the materials making up the package, while channels are continuous open passages across the package seal.

Channel leaks are microchannels that may be found in defective seal areas which are caused by improper product sealing. A wrinkle in a sealing area can form a channel leak because the leak length is significantly larger than the diameter. However, sealing must be maintained to ensure product sterility (Mogmi, Sagi & Park., 2018). Since channel leaks usually have larger depths than pinholes, their leak rates may be much slower. Small leaks (or defects) such as pinholes and channel leaks occur often in food packages during processing and transport because of the limited mechanical resistance of packages (Yam, K.L., 2010)

In addition to channel and pinhole leaks, the package will not seal effectively if there is product such as food on the seal of the package. See the below image of the ham on the seal.

These leaks are breaches that could serve as an entry point for microbes as MAP controls fresh products’ biochemical metabolism, respiration and transpiration (Mogmimi, Kim & Park., 2016). Leaks should be prevented as they can significantly compromise the gas barrier of the package.

4. Package Permeability

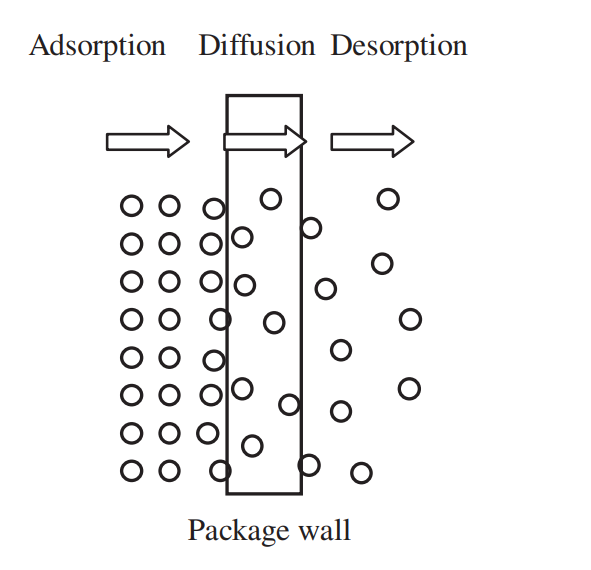

In polymeric packages, gases and vapours pass through package walls (permeation) or through

small leaks (leakage). While leakage through pinholes and channel leaks involves diffusion only, gas permeation through a polymeric packaging film involves a three-step process: adsorption of gas onto one surface of the film, diffusion of gas through the film, and desorption of gas from the other surface of the film. These processes must be carefully considered when used in food packaging where external contamination has to be avoided and the shelf life of food controlled using MAP techniques.

The selection of the best packaging material is a crucial point for the food market because it needs to be versatile enough to withstand handling process forces maintain physical and chemical integrity and be suitable for barrier properties to several gases used in MAP techniques (e.g., O2, N2, CO2). In addition, the intrinsic composition of the packed food (e.g., pH, fat content, aroma compound) may influence the sorption characteristics of the packaging materials, while environmental factors like temperature and, for some polymers, relative humidity may affect their barrier characteristics.

In order to successfully minimise product deterioration with MAP, it is essential to maintain an optimum balance of O2 and CO2 in the packages. The balanced atmospheres are enabled by the selection of suitable film oxygen transmission rate (OTR), respiring surface area, product weight, and respiration rate (Lakakul et al., 1999). OTR refers to the oxygen transfer rate from which gas can permeate through a film and if the OTR is not suitable for the product it will deteriorate.

5. Microbial spoilage

MAP packs with leakages often result in microbial contamination which will reduce the O2 concentration and increase the CO2 concentration. In addition to the package conditions, the microbial spoilage of fresh meats is dictated by the initial microbial quality of the meat, the types of organisms present initially, product storage temperature and time. The incorporation of a particular mix of gases aims to extend the shelf life and reduce the growth of microbes. If the correct concentration of gas mix is not maintained, the atmosphere in the headspace will result in the surface microflora will grow. The main defects in meat are off-odours and off-flavours, but discolouration and gas production also occur. Bacteria associated with the spoilage of refrigerated meat products, cause defects such as sour off-flavours, discolouration, gas production, slime production and a decrease in pH. Most bacteria are more or less inhibited by CO2 and thus the growth rate is reduced, compared to air, and the shelf-life is increased. Indication of microbial growth by detecting an increase in CO2 concentration can be used as a means of determining microbial contamination in other types of products.

Successful Implementation of MAP

MAP is a well-established technique for preserving fresh food by taking advantage of gas ratios surrounding the product that is different from the air. In order for the successful application of MAP, these important factors must be taken into account:

- Appropriate gas mixture suitable for a particular product. The colour of meat is an essential factor in the decision dictating the choice of gasses. These ratios limit microbial overgrowth and toxin production reducing the physicochemical deterioration of packaged foods (Zardetto, 2005b; Chaix et al., 2015).

- Strict Temperature control.

- Composition of the initial microbial association. A large initial population does not ensure the successful application of new packaging technologies.

- Time. The earlier the selection of an association by extrinsic factors begins, the better the results that can be anticipated.

- Permeabilities of the different packaging materials to the gasses used should be selected critically so that the added gasses are retained.

Fill out the contact form below to find out more