Intelligent Sensors for Increased Operational Efficiency

THE GLOBAL PROBLEM:

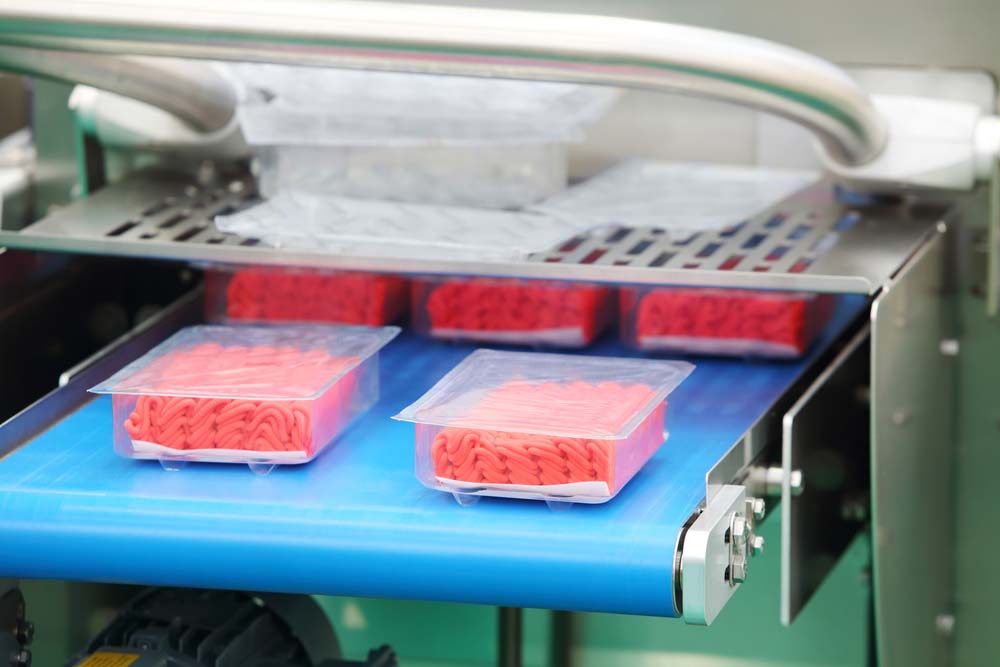

- 3-8% of MAP packs have failed before they reach the supermarket

- HACCP MAP testing incur significant costs for Food Companies

- Most food companies are testing <0.03% of all packs they produce

Our Solution

Optical sensors created from patented food-safe ink that are easily printed into packs to non-invasively monitor in pack atmosphere.

Defective packs are immediately returned to the packing line and repacked, with major savings for the whole food value chain.

Our quality control innovation consists of:

Optical Oxygen Sensor

Based on a patented food-safe ink printed inside the film covering the pack.

Pack integrity test

As the pack approaches the end of line inspection system it goes through a leak accelerator. This device helps accelerate seal and packaging defects and slow leakers.

Inline Scanning System

Reads the sensor output and determines whether a pack is to be rejected. This scanning system can be easily incorporated into existing packing lines. Out of specification packs can be rejected, and the food repacked.

Handheld Scanner

The sensor can be read at any point of the supply chain, from the cold store to the supermarket shelf allowing spot checks of the pack gas levels to be carried out.