Intelligent Sensors for Increased Retail Revenues

- 1/3 of all food produced globally is wasted

- 9 billion MAPs have failed by the retail shelf

- This is costing global retailers over $29bn/year

Senoptica’s sensor technology reduces global food waste by non-invasively monitoring MAP in real time.

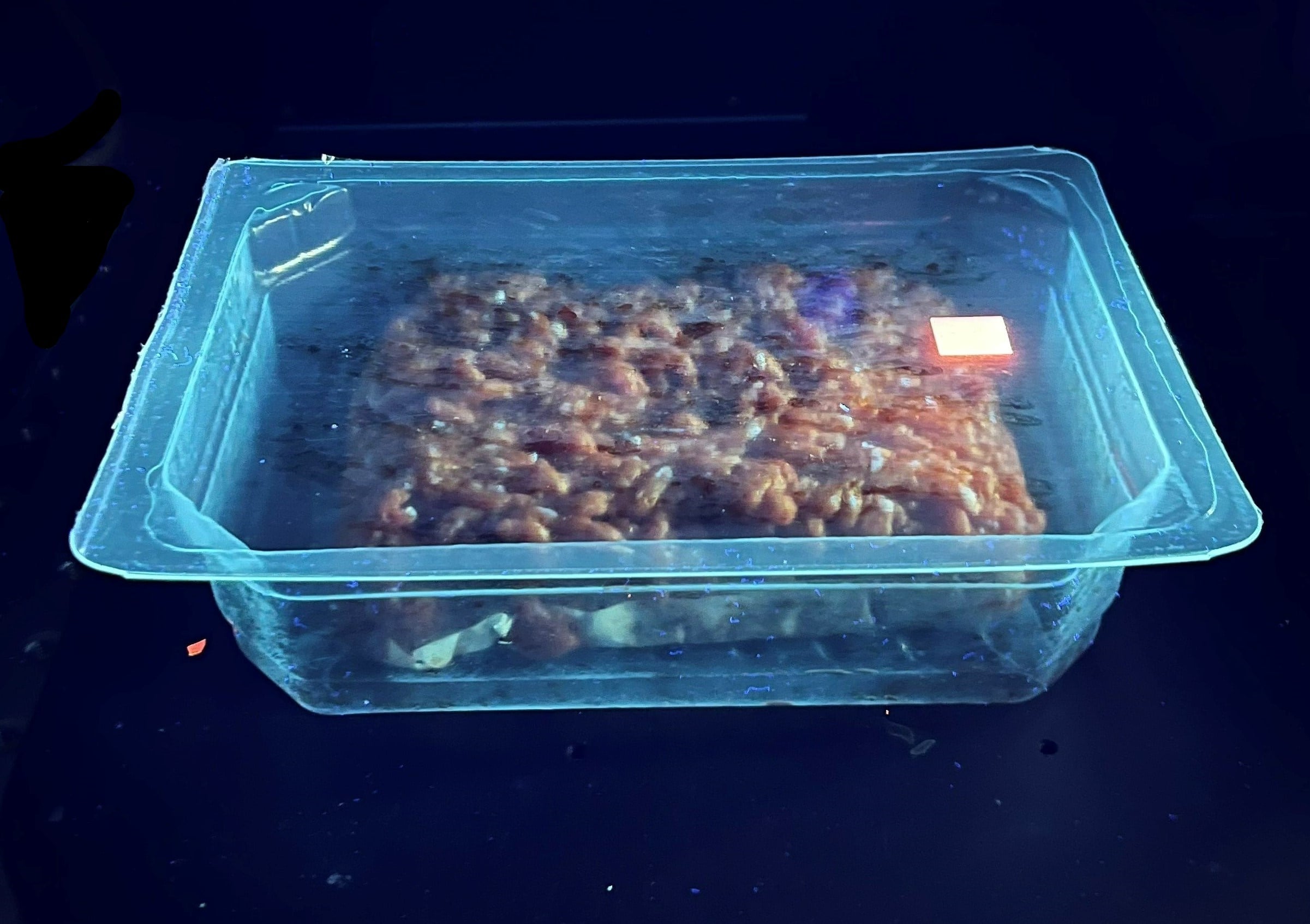

Intelligent Sensors for Modified Atmosphere Packaging (MAP)

The Senoptica oxygen sensor is printed directly into the MAP lidding film.

Once the product has been packed, the sensor is scanned using an in-line scanning system, providing 100% inspection.

Packs are then accepted or rejected based on the specification for that product.

Because the sensor is printed into the packaging, the conditions within the pack can be checked at any point in the supply chain using hand-held devices.

This gives retailers the ability to conduct spot checks on all product entering their supply chain and the information which allows for strategic price downs.

Ultimately, this increases Retailer revenue, reduces food waste and improves consumer satisfaction.

FEATURES

Spot-check packs at supply chain entry points

Check conditions in each pack at daily stock rotation

Predict product spoilage date

Reduction in food waste

Less shopper complaints from premature spoilage at home

BENEFITS

Less failed packs entering the retail supply chain

Opportunity to predict likelihood of spoilage on the shelf

Handheld device prints price down tags so products are sold

Increased category revenues

Improved retailer brand reputation

LATEST NEWS