The Prediction of Meat Spoilage with Indicators

Meat Spoilage

Meat spoilage and shelf life extension are one major focus and challenge of the food industry. Spoilage of meat products is caused by the growth of specific spoilage organisms, found as initial contaminants on fresh packaged meat. Due to the diverse composition of the spoilage microbiome and synergistic spoilage, it is hard to precisely predict the timepoint of spoilage for each individual Modified Atmosphere Packaging (MAP) meat.

On the production line, MAP packaging requires that every Nth package is removed and destructively penetrated with a needle to sample the gases inside. Knowledge of actual gas, specifically oxygen, levels in each pack provides useful information about package integrity, the efficiency of packaging equipment and an indication of product changes. In retail, use-by dates are estimated with a safety margin, frequently resulting in the disposal of unspoiled but still edible meat after exceeding the expiration date (Koskela et al. 2015) or, vice versa, spoiled meat before the use-by date.

Meat spoilage is caused by intrinsic lipid oxidation, enzymatic reactions and also microbial metabolism. This microbial metabolism results in the production of spoilage-associated compounds. A technique regularly used to inhibit microbial spoilage is packaging meat in a modified atmosphere which selectively suppresses the O2 and CO2-sensitive species. Despite the modified atmosphere, meat can be spoiled by bacteria which changes the atmosphere over time. Microbial growth contributes to meat spoil by their ability to produce organoleptically perceptible metabolites called volatile organic compounds (VOCs) (Casaburi et al., 2015).

To find out more about meat spoilage and MAP, check out our previous blogs here.

Prediction of Meat Spoilage in MAP

The prediction of spoilage for each MAP meat product is difficult due to the diversity of spoilage microorganisms. Although use-by dates are used on packs, they are not a true indicator of the product quality through the products life-cycle. It is evident there is a need for precise prediction of the spoilage of individual MAP products. Many methods have been employed to detect pathogens and microbial contaminants; however, some methods, such as traditional colony counting, are excessively time-consuming while others, PCR for example, involve complex instrumentation and handling. All these methods are relatively time-consuming, require experienced personnel and expensive apparatus. The demand for novel technologies for the rapid detection of food spoilage and bacterial contamination becoming increasingly urgent (Scindia et al., 2007).

The low storage temperature of beef alongside the high levels of oxygen in high-O2 MAP acts as a selective barrier for spoilage organisms. Besides retaining the desirable red oxymyoglobin, oxygen also inhibits strict anaerobes. While high oxygen levels generally stimulate aerobes, carbon dioxide inhibits aerobic respiratory growth (Gill and Tan 1980). Meat spoilage can be defined as deterioration towards rejectable organoleptic properties, for example, discolouration, off-odour, slime and excessive exudation (Gill 1983; Borchet al.1996; Gramet al.2002) and is influenced by various intrinsic and extrinsic factors (Rahman 1999).

There is a need for alternative intelligent food packaging technologies, enabling a more precise prediction of the timepoint of spoilage for individual MA packages (Kuswandi et al. 2011). Several nondestructive approaches have been described in recent years comprising sensor technologies to predict meat spoilage by calculating the carbon dioxide, ph, oxygen or pH values.

Enzymatic Indicators For Freshness

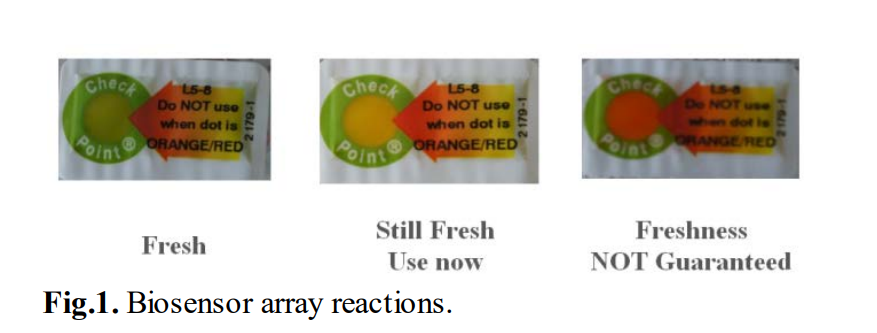

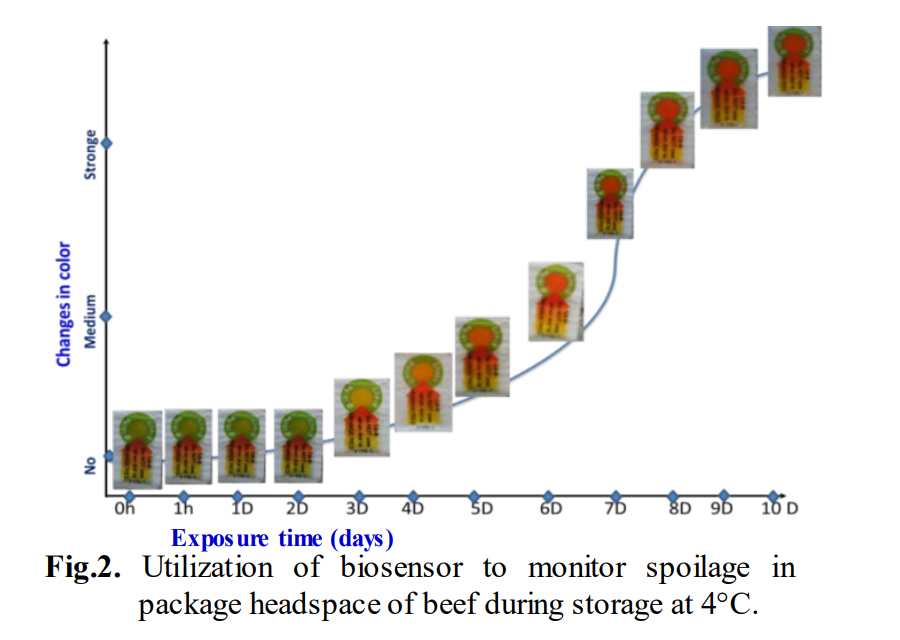

A study which placed a biosensor on a pack of beef, shown in Fig. (1), displays the change in colour to indicate the freshness of the product. In Fig (2), the graph shows the storage of beef over 10 days. In 3 days, no colour change was observed which indicates fresh meat. A gradual colour change was observed from day 4 to 7 gradually this means the beef is still fresh but it should be used soon. After 9 days of storage, there are strong colour changes observed in the biosensor array to red colour, this means that freshness is not guaranteed.

The colour changes of the biosensor array are due to the volatile organic components (VOCs) which are emitted by the meat as a result of enzymatic activities. Early in the storage of the product, the concentration of short-chain alcohols and the hydroxyl group is still low, then increased and microbes started to multiply.

Effect of Oxygen Levels in MAP

During the storage of MAP meat, the initial microbiota grows to high cell numbers, resulting in perceptible spoilage after exceeding a specific threshold level. In addition to the microbiota level, studies have shown that oxygen can be used as an accurate prediction method for meat spoilage due to oxygen consumption in the headspace of MAP (Kolbeck et al., 2021).

Oxygen is one factor that causes food to deteriorate, therefore, a controlled atmosphere such as MAP is an effective solution. However, there is always a risk of leakage in the package, especially during the packaging and distribution process. In addition, the use-by dates are just indicators of the shelf-life and do not accurately reflect the product shelf-life. Oxygen indicators can be a useful solution to help retailers and consumers detect leaks and understand product shelf life.

In MAP beef the oxygen levels will not remain constant during the product shelf-life. The oxygen levels will decrease due to the biochemical activity of the initial microbiota (Hilgarth et al., 2018). Upon oxygen decrease, the increased presence of microbiota results in the detection of a rancid consortium can be detected, resulting in the production of volatile components causing off flavours (Hilgarth et al., 2018). Thus, oxygen consumption in meat packages is directly linked to meat spoilage.

Oxygen Indicators

Intelligent packaging is a packaging system to detect, sense and record any deterioration inside the package to enhance safety, improve quality and indicate any possible problems during food transport and storage (Yam et al. 2005). One example of intelligent or smart packaging is a sensor which can monitor the food quality and safety, such as freshness indication, pathogens, leakage, carbon dioxide, oxygen and pH detection.

Oxygen and carbon dioxide indicators are used to monitor integrity throughout the supply chain through the analysis of the oxygen concentration in MAP and vacuum packed red meat. As a non-destructive method, it checks the impact of oxygen on lipid oxidation (Smiddy et al., 2002). The MAP of fresh red meat usually contains high O2 level (70-80%) and low levels of CO2 (20%) based on the effectiveness of the packaging equipment. Hence, any leakage in MAP will be identified easily by using oxygen indicators.

Fluorescence-based oxygen sensors represent the most promising systems to date for remote measurement of headspace gases in packaged meat products. A number of disposable oxygen sensing prototypes have been developed which may be produced at low cost and provide rapid determination of oxygen concentration (Kerry and Papkovsky, 2002). The active component of a fluorescence-based oxygen sensor usually consists of a long-delay fluorescent or phosphorescent dye encapsulated in a solid polymer matrix (Borchert et al., 2012).

Oxygen Sensor

Oxygen is an essential element for all living organisms and plays an important role in many industrial processes, and the traditional detection methods include gas chromatography and electrochemical techniques. These methods can be expensive and require trained operators, therefore, optical oxygen indicators are fast responding, inexpensive and easy to use (Kozak and Samotyja, 2013).

In recent years there has been a dedicated non-invasive oxygen determination method developed

based on fluorescence quenching of specific optical sensors sensitive to oxygen (Mills, 2005) and

(Wolfbeis and Weidgans, 2006). The method was validated and implemented for common use in 2008

as ASTM F2714-08 standard.

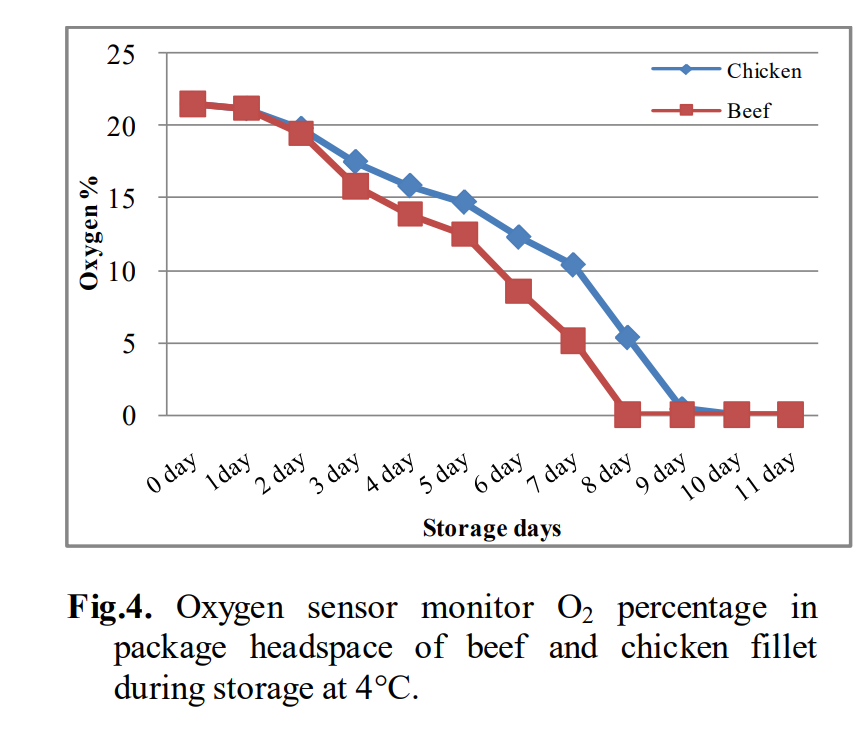

In the study conducted by Morsy et al., 2014, Fig. 4 demonstrates the oxygen percentage in the package headspace of beef and chicken fillet during storage at 4°C using an oxygen sensor. Typically the oxygen content decreased continually. The decrease in remaining oxygen content during storage might be due to the activation of aerobic bacteria that consume the oxygen during the decomposition of nitrogenous compounds. These obtained results generally are in agreement with those previously reported by Papkovsky et al., 2002.

Importance of Indicators to Predict Shelf-Life

According to the European Commission, 60% of the food thrown away in households is edible while in the wholesale and retail sector that figure increases to 83%. Also, up to 10% of food waste generated annually in the EU is linked to date marking. The implementation of indicators on the packaging, specifically oxygen indicators on MAP meat packages, can be hugely beneficial as it enables accurate shelf life prediction and consequently reduces meat disposal as waste.

Traditional food packaging does not provide any information about the quality of food products to consumers and manufacturers at any stage of the supply chain. The essence of new technology to monitor food spoilage from farm to fork is emerged to reduce hazards such as food-borne diseases and also reduce food waste.

Under normal atmosphere packing conditions, when the food within a sealed container starts to spoil, several by-products are formed and they accumulate inside. Therefore, theoretically, it is possible to detect spoilage by detecting one or more of these byproducts. Production of heat, acidity, pressure and carbon dioxide is commonly observed as by-products in food spoilage [Puligundla et al., 2012].

The need for rapid analytical methods in meat industries for quantification of these indicators to determine what kind of processing is suitable for their raw material and to predict the remaining shelf life of their products. Similarly, retail and wholesale need these valid methods to ensure the freshness and safety of their products and in case of disputes between buyers and sellers.

Evidently, a reliable indication of the safety and quality status of meat in from production to the retail level is required to reduce food waste and improve food quality. Senoptica’s optical sensor technology increases quality control and reduces overall food waste. Find out more here.