Freshness of Food

As we move towards a more sustainable and healthy lifestyle, one of the important aspects to consider is food freshness. We all want to consume fresh and healthy food to stay healthy and also reduce food waste. But how can you make sure that the food you consume is fresh and good for you? One way is to look for food freshness indicators. Traditional indicators of food freshness include best-before dates, use by dates, and a smell and taste test.

Typical Indicators of food freshness:

Expiry & Best Before Date

Date codes are intended to help consumers and retailers determine the freshness and safety of food products. They can indicate the date of production, the “sell-by” date (which indicates how long the product can remain on store shelves), the “best before” date (which indicates the date by which the product should be consumed for optimal quality), and the “use-by” date (which indicates the date by which the product should be consumed for safety reasons).

While date codes can provide useful information about food freshness, it is important to note that they are not always reliable indicators of food safety or quality. Factors such as storage conditions, handling, and processing can all affect the freshness and safety of food products, regardless of the date code.

Smell and taste

Smell and taste are often good indicators of food freshness, especially when it comes to perishable items like meat, fish, and produce. However, it is important to note that some foods, particularly aged cheeses and fermented products like sauerkraut and kimchi, may have strong or pungent smells and flavours that are a normal part of their production and ageing process.

While smell and taste can be good indicators of freshness, it is always important to use good judgment and common sense when assessing the safety and quality of food products. Some food products may not show obvious signs of spoilage, but may still pose a risk of foodborne illness if they have been contaminated with harmful bacteria or other pathogens. In general, it is best to follow safe food handling practices, such as refrigerating perishable items promptly, cooking foods to their recommended internal temperature, and discarding any food that appears or smells spoiled.

Innovative Food Freshness indicators

Innovations in freshness for food are improving the accuracy and effectiveness of food freshness and thus, reducing food waste and improving sustainability in the food industry. Here are a few examples:

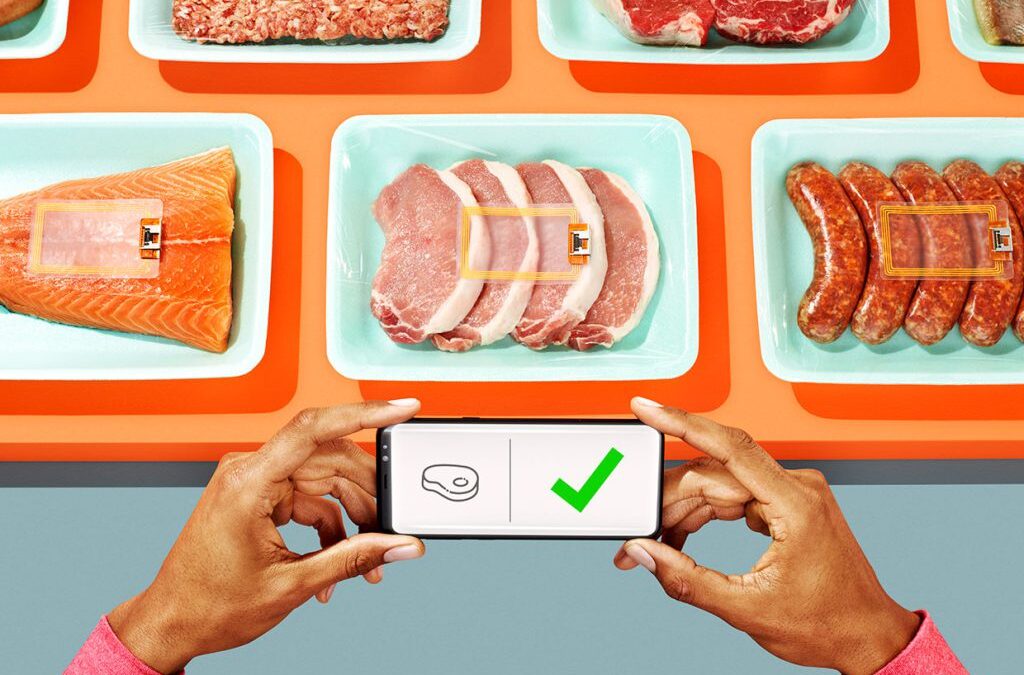

Smart packaging:

Smart packaging technologies like active and intelligent packaging can be used as freshness indicators by incorporating sensors, indicators, and other technologies to monitor the quality and freshness of food products. For example, some smart packaging technologies are time-temperature indicators, oxygen indicators, pH indicators, and biosensors, which signal when a food product has spoiled. An example of smart packaging is biosensors.

Biosensors are increasingly being used as food freshness indicators, and offer several advantages over traditional methods such as visual inspection or date codes. Biosensors are devices that use biological materials, such as enzymes, microbes, antigens or antibodies, to detect and measure the presence of specific compounds or microorganisms (Park et al., 2015). In the context of food freshness, biosensors can be designed to detect changes in the levels of gases, such as ammonia or carbon dioxide, or to detect the presence of specific microorganisms that are associated with spoilage.

One of the key advantages of biosensors is that they can detect changes in food freshness at an early stage before they become visible to the naked eye or detectable by traditional means. This can help to reduce waste and improve food safety, by allowing consumers and retailers to identify and discard spoiled food more quickly.

Another advantage of biosensors is that they can be designed to be highly specific and selective, meaning that they can detect specific compounds or microorganisms with high accuracy and sensitivity. This can help to reduce the risk of false positives or false negatives, which can be a problem with traditional methods of food freshness testing (Yasmin et al., 2016).

In order to maintain the small size requirement for packaging material, most of the biosensors cannot display the full history of freshness quality-indicating parameters, but can only show the current status. Therefore, the use of biosensors combined with RFID enables the continuous monitoring of the quality such as the changes in metabolite concentration during food storage. RFID is an electronic, information-based form of smart packaging that transmits real-time information to trace and track the history of more complex information including temperature and relative humidity(Park et al., 2015). Overall, biosensors are an important tool for smart packaging and are likely to play an increasingly important role in food safety and quality control in the future.

Blockchain Technology

Blockchain technology is another emerging technology that is being explored for its potential use in food freshness indicators. Blockchain is a digital ledger that allows for secure, transparent and tamper-proof record keeping of transactions. It has several features that make it useful for food safety and quality control:

1. Digital identity:

A unique digital identity can be created for each food product at the point of origin. This digital identity would contain information such as the date of harvest/production, location of origin, and any other relevant data that would help in tracking the freshness of the food product.

2. Recording of data:

Blockchain technology can be used to track the entire journey of a food product from farm to table, providing transparency and accountability at every step of the supply chain. This can help to ensure that food products are handled and transported safely, and can also help to reduce the risk of food fraud. For example any subsequent changes to the food product’s location or condition along the supply chain. Such as, if the food product is transported to a different location, the temperature at which it is stored, and any other relevant information can be recorded on the blockchain (Casino et al., 2019).

3. Verification of data:

The information recorded on the blockchain can be verified by multiple parties, such as farmers, suppliers, and retailers, to ensure that the food product’s freshness is accurately represented. This can be done using smart contracts, which are self-executing contracts with the terms of the agreement directly written into code.

4. Consumer access to information:

Consumers can access this information by scanning a QR code on the food product’s packaging. This QR code would provide information about the food product’s digital identity, as well as any relevant information about the food product’s freshness and safety.

Using blockchain technology to track the freshness of food products can help improve food safety and reduce waste. By providing consumers with accurate information about the food they are buying, they can make more informed purchasing decisions and reduce the likelihood of consuming expired or contaminated food products.

Oxygen Indicators for Food

Oxygen (O2) is also an important factor to consider in the food industry, as it can affect the quality and safety of food products. Oxygen indicators are commonly used as a food freshness indicator as they provide a visual indication of the amount of oxygen present in a food package, which can indicate the freshness of the food. The principle behind oxygen indicators is based on the fact that oxygen is one of the main factors that contribute to the deterioration of food. When oxygen reacts with food, it can cause spoilage, discolouration, and the growth of microorganisms that can lead to foodborne illnesses. By providing a clear visual indication of the oxygen level inside a package, consumers and retailers can quickly and easily determine whether a product is still fresh or has started to spoil and can make informed decisions about whether to consume or discard the product.

Oxygen sensors:

Oxygen sensors can be used in a variety of food packaging applications, including vacuum packaging and modified atmosphere packaging (MAP), which involves altering the atmosphere inside a package to preserve the freshness of the food. MAP typically involves reducing the oxygen level inside the package to slow down the growth of microorganisms that can cause spoilage. Oxygen sensors typically consist of a sensing element that reacts to the presence of oxygen and a signal processing unit that converts the sensor output into a measurable signal. The sensing element may be made of various materials, such as zirconium oxide or electrochemical cells, that are sensitive to changes in oxygen concentration.

By using oxygen sensors in conjunction with MAP, it is possible to monitor the oxygen level inside the package and ensure that it remains at the desired level. When an oxygen sensor is placed inside a food package, it measures the oxygen concentration in the headspace of the package, which is the area between the food and the package. The sensor may be placed in a specific location within the package to ensure that it provides an accurate measurement of the oxygen concentration. If the oxygen level starts to rise, indicating that the package has been compromised or the food is no longer fresh, the sensor can provide an alert, allowing the food to be discarded before it spoils.

In addition to oxygen indicators, gas sensors can also be used in MAP with meat products to monitor the levels of other gases, such as carbon dioxide and nitrogen, which are used to modify the atmosphere inside the package. These sensors can provide a more comprehensive indication of the freshness of the meat, as changes in the levels of these gases can indicate the growth of spoilage bacteria and other microorganisms.

Oxygen Sensors and Meat

Oxygen indicators are commonly used in modified atmosphere packaging (MAP) with meat products to indicate the freshness and spoilage of the meat. MAP is a technique that involves altering the composition of the air inside a package to slow down the growth of bacteria and other microorganisms that can cause spoilage.

Meat products are particularly susceptible to spoilage due to their high protein content, which provides an ideal environment for bacteria to grow. MAP is an effective way to extend the shelf life of meat products by reducing the amount of oxygen in the package, which inhibits the growth of spoilage bacteria and slows down the rate of oxidation that causes discolouration and off-flavours.

Oxygen indicators can be used in MAP with meat products to monitor the oxygen level inside the package and provide an indication of the freshness and spoilage of the meat. Typically, oxygen indicators will change colour or have a visual indicator that signals when the oxygen level inside the package has reached a certain threshold. This provides a clear visual indication of the freshness of the meat and can help to ensure that consumers and retailers do not sell or consume meat that has begun to spoil.

Carbon Dioxide Indicators

Carbon dioxide (CO2) is commonly used in the food industry as a preservative and as a way to control the atmosphere around food products. Specifically, CO2 is one of the key gases used in MAP to reduce the growth of spoilage microorganisms and inhibit enzymatic browning. Monitoring CO2 levels is important to ensure food safety and quality. Here are some common CO2 indicators used in the food industry:

1. pH indicator strips:

CO2 dissolves in water to form carbonic acid, which lowers the pH of the surrounding environment. pH indicator strips can be used to test the acidity of food products to determine the levels of CO2 present.

2. Carbon dioxide detectors:

These are electronic devices that measure the concentration of CO2 in the air. They are commonly used in food storage areas and refrigeration units to ensure that CO2 levels are within safe limits.

3. Time-temperature indicators:

These indicators are used to monitor the temperature and time that food products are exposed to certain levels of CO2. They can help to determine whether food has been stored properly and whether it is safe for consumption.

4. Respiration rate monitors:

These devices measure the respiration rate of fresh produce, which can be used to calculate the rate of CO2 production. This information can help to determine the freshness and quality of the produce.

5. Optical Sensor

One type of CO2 sensor commonly used in MAP is an optical sensor, which works by measuring changes in the refractive index of a fluorescent indicator dye in response to changes in CO2 concentration. These optical sensors are often integrated into the packaging material itself, allowing for non-invasive monitoring of the CO2 levels inside the package. The data from the sensors can then be used to adjust the gas composition or temperature inside the package as needed to maintain optimal freshness and quality of the food.

Overall, monitoring CO2 levels is important in the food industry to ensure food safety and quality. Different CO2 indicators may be used depending on the specific application and the type of food product being monitored.

The freshness of meat

In order to determine the freshness of meat using an indicator/sensor, it is imperative to understand the mechanisms of meat spoilage to detect these intermediate compounds during spoilage as a quantitative measure of freshness. Tissues from meat products, including beef, pork, and poultry, are mainly composed of proteins, lipids, carbohydrates, inorganic matter, and moisture, and thus their spoilage mechanisms are similar. Microbial growth, oxidation, and enzymatic autolysis are the three main mechanisms responsible for meat spoilage.

During meat spoilage, proteins and lipids break down and form new compounds that negatively impact the quality of the meat products. Microorganisms can act on proteins via proteolytic activity and transform them into smaller compounds, such as free amino acids. These amino acids undergo oxidative deamination, decarboxylation, and desulfurization, resulting in NH3, CO2, and H2S. In addition to these, another indicator of the microbial decay of proteins in food is high levels of highly total volatile basic nitrogen (TVBN), such as ammonia, dimethylamine (DMA), and trimethylamine (TMA). Changes in the colour of pH dyes can be used to detect acidic or basic volatile compounds (Lee & Shin, 2019)

Three types of criteria are usually employed to determine beef quality: sensory, microbiological, and chemical. However, often these methods to determine beef quality have a number of disadvantages, including time-consuming detection processes, low accuracy, and/or high costs. Therefore, in order to evaluate the quality of meat a simple, low-cost, and highly efficient method is necessary. This would allow consumers to directly determine the freshness of meat (Kuswandi and Nurfawaidi, 2017).

Senoptica’s optical sensors are created from patented food-safe ink that is easily printed into packs to non-invasively monitor the pack atmosphere. The inline scanning system Reads the sensor output and determines whether a pack is to be rejected. This scanning system can be easily incorporated into existing packing lines. Out of specification packs can be rejected, and the food repacked. In addition, the handheld scanner can read the sensor at any point of the supply chain from the cold store to the supermarket shelf allowing spot check of the pack gas levels. To learn more about Senoptica’s freshness indicator click here.

The Importance of Food freshness indicators

Freshness indicators provide information about product quality based on chemical changes or microbial growth in the food product. Food freshness indicators (FFI) are a cost-effective intelligent packaging approach which is applied for the real-time detection and monitoring of the freshness/spoilage status of food and informing food conditions to the consumers.

An appropriate FFI should have the ability to distinguish fresh, medium fresh, and spoiled food typically by the naked eye. Some important parameters such as the type of halochromic colourants and polymer used in the FFI and the method of preparation can directly affect the performance of the FFI (Almasi et al., 2022). Perishable products lose their freshness and shelf life fast when exposed to high temperatures. Product date codes are helpful to indicate freshness but are accurate only when products are kept within proper temperatures. Research indicates that the incidence of food waste would be reduced if the shelf life of food products were not guesswork. Intelligent packaging containing consume-within (CW) technology can communicate to consumers the shelf life of products after they are opened.